DSH double helix conical mixer

Applications: Double spiral conical mixer (double spiral mixer) can be widely used in various industries such as chemical industry, battery raw materials, pigments, coatings, dyes, pesticides, pharmaceuticals, food, feed, additives, refractory materials, new materials, electronic plastics, rubber, ceramics, fertilizers, metallurgy, mining, dry powder mortar, special building materials, etc. for powder and powder mixing, as well as for mixing liquid and liquid, powder and liquid Solid liquid (i.e. adding liquid to the powder) mixture.

Double spiral conical mixer (double spiral mixer) can be widely used in various industries such as chemical industry, battery raw materials, pigments, coatings, dyes, pesticides, pharmaceuticals, food, feed, additives, refractory materials, new materials, electronic plastics, rubber, ceramics, fertilizers, metallurgy, mining, dry powder mortar, special building materials, etc. for powder and powder mixing, as well as for mixing liquid and liquid, powder and liquid Solid liquid (i.e. adding liquid to the powder) mixture. This machine has strong adaptability to mixtures: it will not overheat thermosensitive materials; Will not crush or grind granular materials; The mixture of materials with significant differences in weight and particle size will not experience stratification and segregation; For the mixing of various particles, fibers, or sheet-like materials such as coarse, fine, and ultrafine powders, the double helix conical mixer is also a container fixed mixer. Compared with other mixers, the double helix conical mixer has the advantages of low installed power, wide adaptability to mixed materials, and no damage to mixed materials. It does not overheat thermosensitive materials, does not feed or grind granular materials, and does not produce layering and segregation when mixing materials with significant differences in weight and particle size. It also has good adaptability to the mixing of coarse, fine, and ultrafine particles (at the nanoscale).

The machine mainly consists of a transmission system, two inclined screws, a rotating arm, a cylinder, a discharge valve, etc. Two working screws are parallel to the generatrix of the conical cylinder, symmetrically distributed on both sides of the centerline of the cone, and intersect at the bottom of the cone, connected to the central pull rod. The upper parts of the two screws are respectively connected to the transverse arms extending from the center to both sides, forming a mechanically symmetrical and balanced inverted triangle structure, including:

(1) Transmission system: The rotational motion of a spiral shaft and its circular motion along the cylinder wall with the rotating arm. The revolution and rotation adopt a separate transmission method, and both parts use a fixed cycloidal pinwheel reducer with high speed ratio and efficiency, which is distributed and reversed through bevel gears and transmitted to the two rotating arms.

(2) Cylinder: The container of this machine is made into an inverted cone, with the purpose of ensuring sufficient material alternating circulation under the lifting action of the screw. Therefore, the container must have an appropriate cone angle. Based on production experience, usage conditions, and calculations, the basic size series, full volume, cone angle, and container height of the "double helix conical mixer" have been determined.

(3) Rotating arm, central rod, and screw: The screw is composed of a screw and a spiral plate, and it is a direct working component for mixed materials. In order to ensure the stiffness of the screw, reduce weight, and facilitate the welding of the screw, a. 20 steel pipe is used in the design for the screw. Spiral blades are welded in the right rotation direction with a certain diameter and pitch. The upper end of the screw is connected to the cross arm, and the lower end is connected to the center pull rod, symmetrical on both sides. The connection form of this triangular symmetric load-bearing component is force balanced, improving the load-bearing state of the component. The lower end of the screw can rely on the central pull rod to pull and support independently of the container, without the need for a fixed bottom support structure at the bottom of the equipment.

(4) Discharge valve (misalignment valve, plum blossom valve): The bottom bearing of the equipment has been removed, which is conducive to discharge. This machine is designed with a discharge valve consisting of two overlapping fan hole plates. The valve has a simple structure, does not occupy any space, and the size of the discharge hole can be freely controlled. The operation is simple, and the material can be completely discharged. It can also be easily disassembled and washed, making it beneficial for cleaning and repairing equipment. In short, the double helix conical mixer has the advantages of not damaging particles, not heating and deteriorating, and not segregating and layering. Without damaging the mixture, it generates composite movements such as lifting, convection, shearing, and diffusion inside the cone, which can gently mix materials and achieve the mixing effect.

Working principle:

The rapid rotation of two asymmetric spirals inside the mixer cylinder lifts the material upwards, forming two asymmetric screw shaped material flows from bottom to top along the cylinder wall. The rotating arm rotates slowly, causing the material outside the spiral to enter the screw envelope to varying degrees. Some of the material is lifted in a staggered manner, while the other part is thrown out of the screw, achieving continuous updating and diffusion of the material in all circumferential directions, The two materials mentioned in the upper part converge towards the central cavity, forming a downward material flow that supplements the bottom cavity and creates a triple mixing effect of convective circulation.

Structural characteristics of cycloidal pinwheel reducer models:

The structure of the cycloidal needle reducer is composed of a reducer, cylinder cover, cylinder body, transmission part, screw, discharge valve, and other parts.

1. Reducer: planetary cycloidal pinwheel, dual stage, dual output shaft reducer, with two output speeds: revolution and rotation.

2. Cylinder cover section: The cylinder cover supports the entire transmission section, which is fixed to the cylinder cover with bolts. There are several openings on the cylinder cover for feeding, observation, cleaning, and maintenance.

3. Transmission part: The reducer passes through the transmission distribution box, causing the rotating arm, transmission head, and screw to perform planetary revolution and self rotation motion.

4. Cylinder part: The cylinder is a conical structure, which allows for quick discharge, no accumulation, and no dead corners.

5. Spiral part: Two asymmetrically arranged propellers inside the cylinder rotate themselves and perform planetary motion under the transmission of the distribution box, flipping the material within the range of the cylinder to quickly achieve uniform mixing.

6. Discharge valve: The discharge valve is installed at the bottom of the cylinder to control materials and discharge them. The discharge valve of this machine can be divided into three forms: pneumatic, pneumatic, and electric.

7. Spray device (optional): The spray device consists of pipe fittings and nozzle components, and is fixed on the cylinder cover.

Structural characteristics of worm gear and worm gear models:

1. Spray device: The spray device consists of a rotating head and spray components. The spraying component is fixed to the lower cover of the transmission distribution box with a flange, and is driven by a revolution to operate together. The rotary joint and the spraying component are movable connections, so that the rotary joint is fixed on the pipeline. This mixer should be equipped with an infusion pump to evenly atomize or add liquid into the pipeline, in order to meet the requirements of material mixing.

2. Transmission components: The movement of the revolution motor and the rotation motor is adjusted to a reasonable speed through worm gears and gears, and then transmitted to the screw to achieve both revolution and rotation movements.

3. The configuration of the cylinder cover, cylinder body, spiral part, and discharge valve is the same as that of the cycloidal pinwheel reducer model.

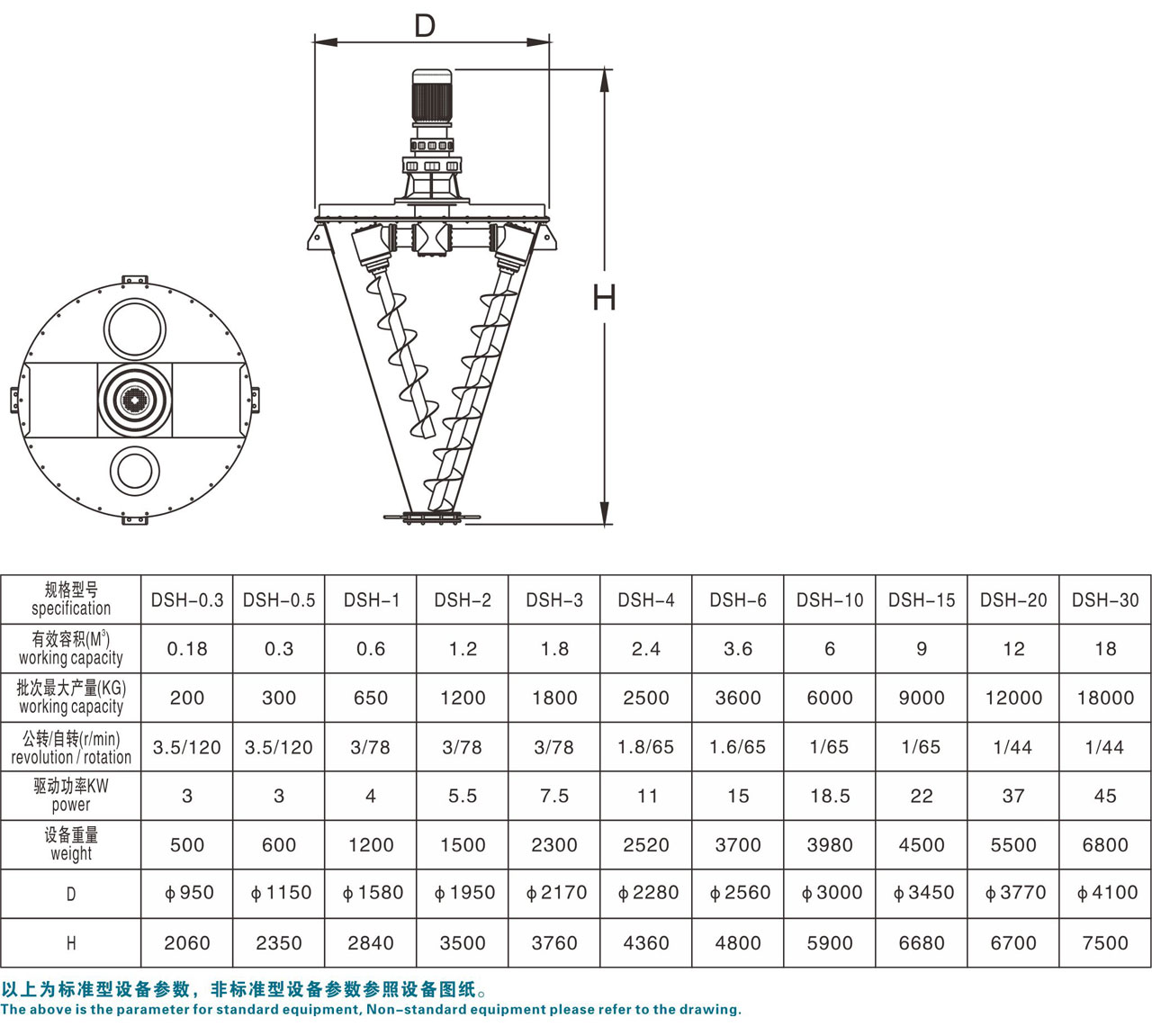

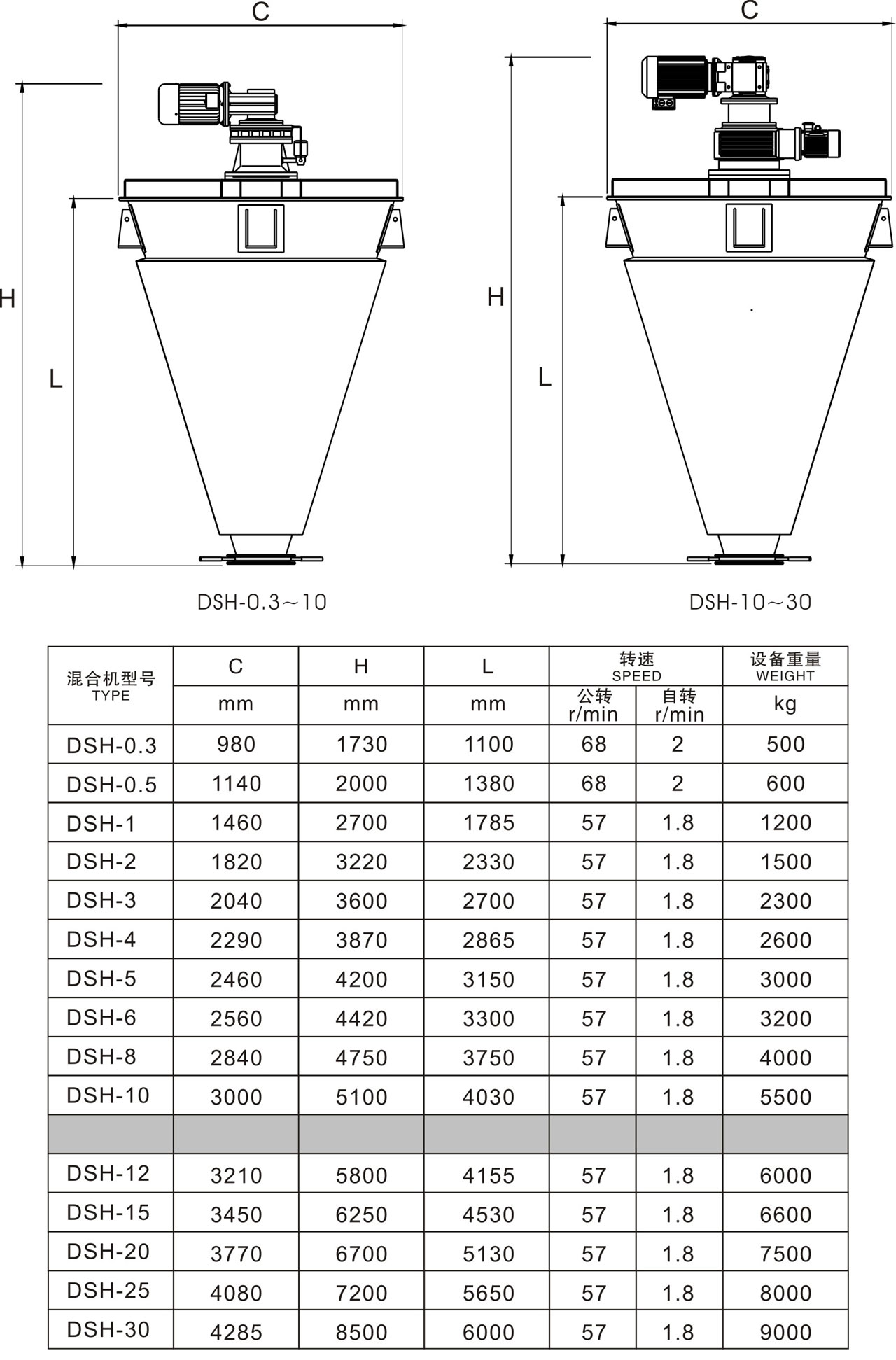

Technical parameters: